5.1.2020

The successful year of 2019 is behind us. We completed and deploy several projects, other big tasks are ahead of us.

Our first application using artificial intelligence is Aipha - system for finding faults and various operating deviations in photovoltaic power plants. Neural network used in this application is relatively simple, but it performs its task perfectly.

Artificial intelligence, computer learning, machine learning, deep learning - the name doesn't matter - is however, in itself a very interesting field. Artificial intelligence can be used to efficiently process data that would otherwise be unworkable - an example is Aipha or face recognition (In practice, our new gatekeeper can do this).

The entry barrier into the technology is relatively high:

In 2019, we crossed the barrier partially at least. Mathematical models associated with photovoltaics work well, practical deployment for monitoring and subsequent data processing are still waiting for us.

The company Robe manufactures lighting equipment. In Rožnov, for example, the company installed bridge lighting. Robe assembles its products in Valašské Meziříčí. For the company we developed a system to trace their production. Production number of each component built in a product is recorded to database. Thanks to the system the Robe company has better overview of its product. For each component they know specific manufacturer, serial number, version, batch operator, date of assemble and more and more information.

The application runs on a cheap computer Raspberry Pi with touch screen. Operators enter data using a QR code reader and application is developed specifically for it's purpose. It is very easy to work with the system. Data are stored on a database server and it is possible to operate the application safely even in a normal internet environment.

Other category of aplications is a firmware for Vacushape threadmill. Ordinary running belt is enclosed in a sealed hood. Runner's lower part of body is enclosed and exposed to underpressure or overpressure. Thanks to the pressure difference the body can be shaped much more efficiently.

Application runs on an embedded computer with touch screen. This is similar to the Robe production tracing application, the same technology is used. The application controls the entire machine - length of exercise, pressure intensity, speed and other parameters. An overview of the course of the exercise is available in the form of graphs, it is planned to save the entire history of the exercise on a web portal.

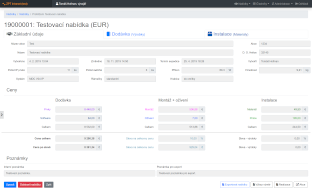

Company ZPT Vigantice manufactures and sells communication systems for medical and social facilities. Its sales department need a tool that help them to create the offer: select all components needed, calculate prices an print the completed offer. It must work in four languages. Although the development of this system began in 2018, during the last year all important functions were completed and used by salesmen. The system replaces the older unsustainable process based on Microsoft Excel sheets.

In the information system the user can define product properties like the mass, power consumption, multilanguage description and images. Also the relations between various products are defined so when the user add one product to the project then the corresponding ammount of other material were added automatically. The system generate PDF file with complete offer to the customer. Also the complete BOM (bill of material) for the production department is available.

The information system is built on web technologies with emphasis on security for remote access.

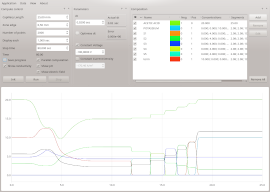

In cooperation with Charles University in Prague we develop an application for electromigration analytics methods. The computational engine is based on numerical solving of differential equations using Runge-Kutta method. Of course, that's something that nobody in Hobrasoft can understand. But there is also a lot of interesting work on the user interface. Data for simulation must be created, displayed during calculation and saved for later processing.

The calculations demand extreme amount of CPU power so the application must work very fast and it must be able to use multiple cores of the CPU. I like the application. I love when the CPU fan spins at 100% and the computer begins to do what it was create for - compute!

I love the job and cooperation with Bohuslav Gaš.